Products List

【Features】:Quinoa Threshing Machine can also process wheat, paddy, barley, oat, rye, millet, sorghum, beans, etc. It has double air duct re-sucker, which can thresh the crops again after the first round of threshing if necessary to have thorough threshing.

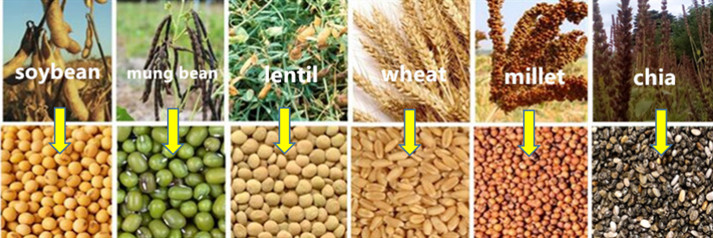

UGT-125 Quinoa Threshing Machine can THRESH AND CLEAN various crops seeds, like quinoa, sesame, chia, hemp seeds, wheat, paddy, barley, oat, rye, millet, sorghum, soybeans, lentils, mung beans, chickpeas, giant beans, peas, broad beans, fennel (aniseed), etc. It is one upgraded multi-purpose crops thresher with large capacity 2-3T/Hour.

We design the most complete and reasonable configuration for UGT-125: sufficient spare parts for at least 3 years of use, and electric-start method with automatic-charging battery for the diesel engine!

This model has been exported to Bolivia, India, Tanzania, Canada, Australia, etc.

UGT-125 Quinoa Threshing Machine Working Principle:

It mainly consists of a feed hopper, a drum, a concave plate, a shelf, sieves, etc..

During working, the crops are fed continuously and evenly into the machine, and the seeds are separated from the stems by friction, extrusion, collision, and shaking of the rasp-bar and the concave plate assembly on the drum. Then the seeds are discharged from the concave plates, and the stems are ejected by the centrifugal action of the drum, and the threshing process is completed. We only need to replace the suitable sieve for each kind of seeds when threhing.

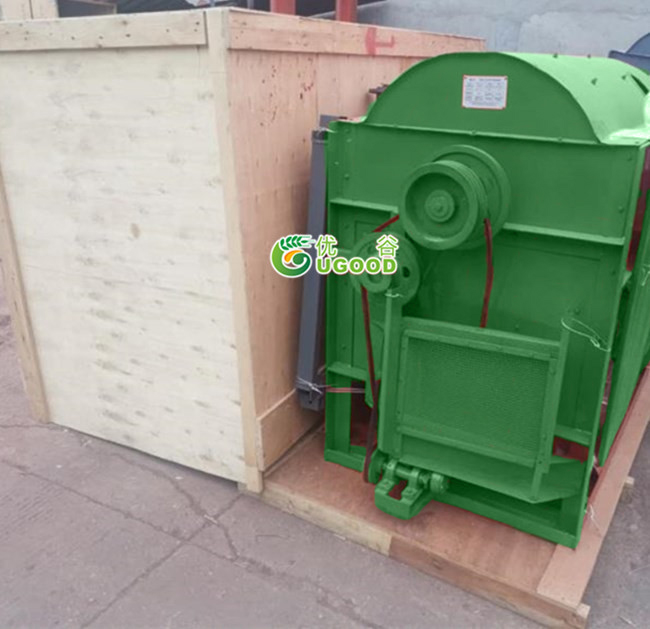

Pictures of delivery to Bolivia:

VIDEO:

Safe use of the thresher:

(1) Due to the tight work of the thresher and the harsh environment, the personnel who participate in the threshing operation should be educated in safety and operation, so that they can understand the operating procedures and safety common sense, such as the sleeves should be tight, masks and protective glasses should be worn.

(2) Before using the thresher, it is necessary to carefully check whether the rotating and swinging parts are flexible and non-collision; check whether the adjusting mechanism is normal and the safety facilities are complete and effective; ensure that there is no sundries in the machine, and the lubricating parts should be filled with lubricating oil.

(3) Before the threshing machine is turned on, the working site should be cleaned up, and some sundries not related to threshing should not be placed; children should not be allowed to play on the site to avoid accidents.

(4) When feeding, it should be evenly fed. The crops should be directly pushed into the drum. Strictly prevent stones, sticks and other hard objects from being fed into the machine.

(5) The joint of the transmission belt should be firm; it is strictly forbidden to pick up the belt when the machine is running or touch any object to the transmission part.

(6) The transmission ratio between the selected supporting power and the thresher should meet the requirements, so as to avoid the high speed of the thresher, the vibration is severe, and the parts are damaged or the fasteners are loose.

(7) The threshing machine can't work continuously for too long. Generally, it works for about eight hours. It is necessary to stop for inspection, adjustment and lubrication to prevent severe friction and heat deformation.

(8) The thresher is generally powered by a diesel engine. Wear an anti-inflammatory cover on the exhaust pipe to prevent fire.

(9) If the threshing machine fails during the operation, it should be shut down for maintenance and adjustment, and it must not be dealt with in order to avoid further failure.

The repair of the thresher:

(1) After the threshing is finished, the dust and sundries in the machine should be carefully removed; paint should be repainted as required during the use of the paint.

(2) The parts of desoldering and cracking should be welded.

(3) For installation of the rasp bar, please note that the small head (beveled) should be oriented in the feeding direction, and the grain direction of the adjacent two rasp-bars should be reversed to prevent the grain from moving to one end of the drum, resulting in uneven load.

(4) Tighten the stud bolts to the specified torque. Generally, it is tightened 3-4 times; check whether each stud bolt has a lock nut. Because the threaming machine works, the roller is running at a high speed, the nut is easy to loose, and the quality of the rod must meet the requirements. It cannot be replaced by other bolts.

(5) After the repair of the thresher drum, static balance adjustment should be done until the balance is adjusted.

(6) Check if the thruster guard cover is firm and replace it if it is damaged.

(7) Complete maintenance, fill a sufficient amount of lubricating oil to each oil filling point and lubrication point, and apply oil and rust on the threads of each adjusting screw; place the thresher in a dry and ventilated shed, taking care not to be in the thresher Remove debris from the top to prevent deformation.

Exempting the middlemen, the producers directly meet with the users, simplifying the circulation process and shortening the circulation time to achieve the real factory preferential price.

UGT-125 Quinoa Threshing Machine Features:

The machine has double air duct sucking disc, which can thresh the crops again after the first round of threshing if necessary to make the crops have thorough threshing and separation.

It belongs to large capacity of feeding type crops thresher. It can thresh crops with the crops stalk. This model is quite popular with farmers from different areas.

UGT-125 Quinoa Threshing Machine Technical Parameter:

Whole machine size: 2.0m *1.8m *1.4m

Weight: 450kg

Air blower quantity: 3

Power: 11-15KW motor(380V, 1400 turns), or 22-25HP diesel engine

Capacity: 2-3T/Hour

It has double threshing drums.

Any change of technical parameters, there is no further notice.

Copyright: Zhengzhou UGOOD Machinery Equipment Co., Ltd. info@corn-thresher.com Tel: 0086-135-2306-3891 Address: No. 7 Gaocun Guanzhuang Industrial Park, Zhengzhou, Henan, China