- Home

-

About Us

-

Products

- Corn Husking Machine

- Large Seeds Corn Husking Line Dry Corn Bracts Leaves Peeling Machine Maize Husker

- Small Specific Fresh Green Sweet Corn Husker Corn Shucking Machine CE Certificate

- Large Sweet Corn Husking Machine Wet Corn Husker Maize Husking Processing Line

- Corn Threshing Machine

- PTO Large Portable Maize Shelling Machine Maize Sheller Corn Thresher

- UGT-07 Fully Automatic Corn Threshing Machine

- UGTL-1 Large Capacity Maize Thresher

- Husking & Threshing

- UGT-07 Corn Husking and Threshing Machine Driven by Tractor 24HP

- UGTL-2 PTO Large Maize Husking and Threshing Machine

- Large Corn Threshing Line Maize Husking Threshing Cleaning Plant Automatic Equipment

- Push Seed Planter

- Rice Paddy Nursery Sowing Machine Semi Automatic Seeding Machine

- Garlic Planting Machine Seeding Sowing Seeder Planter 3 4 5 6 Row with Tractor

- Nursery Seeding Line Pneumatic Needle Aspiration Precision Seeder

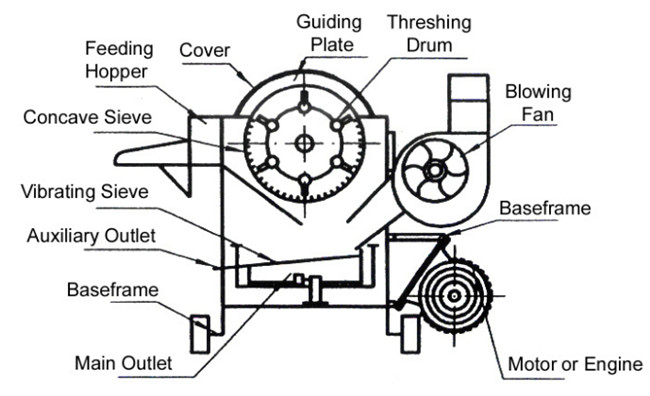

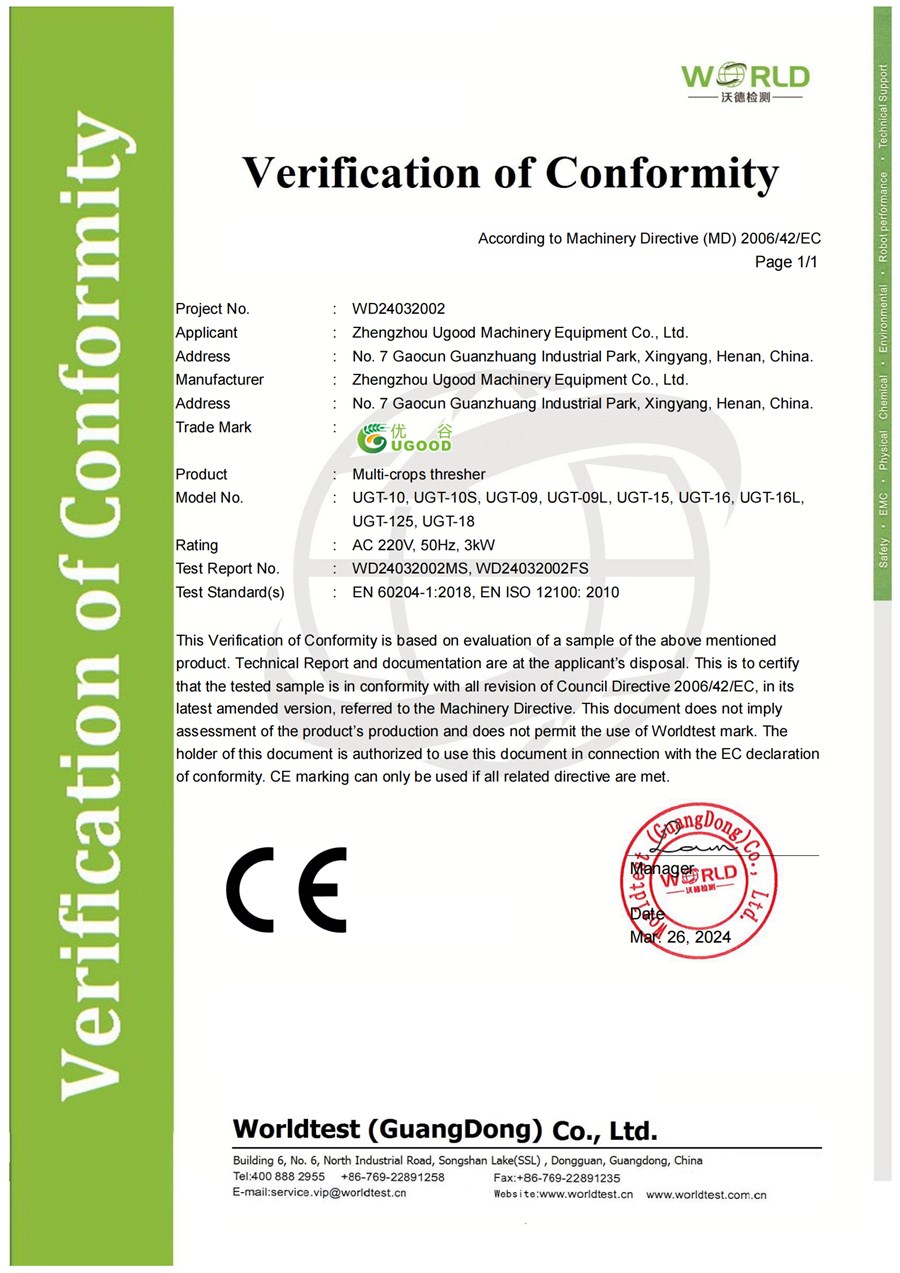

- Multi-crops Thresher

- Small Seeds Thresher Experimental Use for College Wheat Barley Oat Seed Threshing

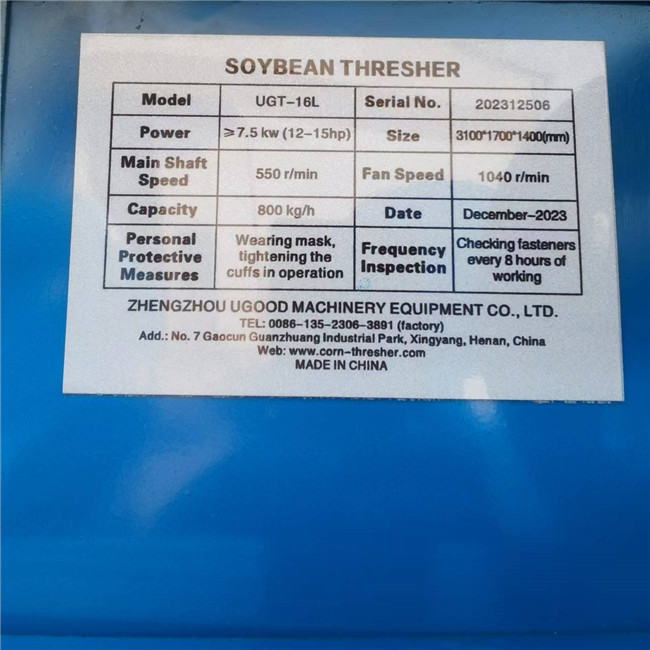

- UGT-16L Multi-crops Thresher Soybean Paddy Quinoa Wheat Maize Safflower Threshing Machine

- UGT-16 Portable Multi-crops Paddy Wheat Millet Beans Thresher

- Chaff Cutter

- Mash Feed Production Line Livestock Poultry Feed Processing Plant

- Silage Forage Fodder Chopping Cutting Machine Straw Rubbing Kneading Silk Machine Shredder

- Chaff Hay Straw Grass Cutter Grain Grinder Combined Machine Maize Corn Cobs Crushing Grinding

-

Video

-

News

-

Contact Us

-

info@corn-thresher.com