Products List

Multifunctional Bambara Nut Flour Grinding Machine or bambara nut grinder, bambara flour milling machine, can grind many different crops or grains, such as bambara nut (also called vigna subterranea, Bambara-bean, Congo goober, earth pea, ground-bean, or hog-peanut), Maize,Beans,Sorghum, Plantain, Wheat, Rice, Cassava and so on.

It can be also used in cutting and rubbing maize straw, hay, potatoes seedling and weed. It is the ideal and professional grinding mill for the self-employed, farmers, livestock staff and animal feed factory.

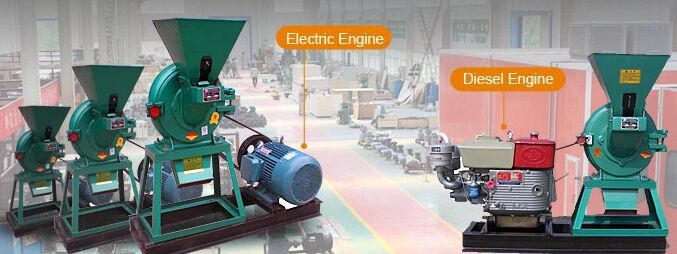

With diesel engine:

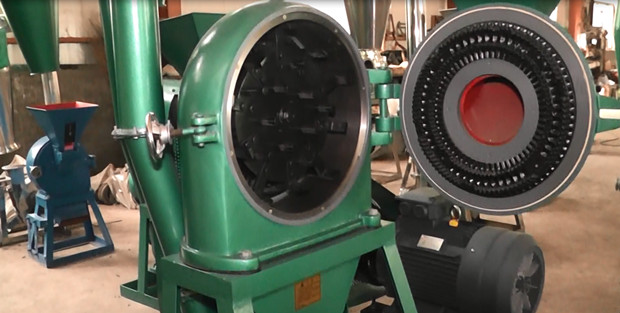

With fan, discharger devie, motor, etc.:

The bambara nut flour grinding machine can also grind other various kinds of grain seeds:

Please tell us:

1.Model + whole name of the machine

2. Your raw material (which kind of grain) & end produts (powder) meshes

3.Whether need of diesel engine or electric motor

4.Whether need of fan and discharger

Then we can quote you the exact price.

Introduction:

The multifunctional Bambara Nut Flour Grinding Machine can grind bambara nut, maize, rice, soybean, peas, mung bean, chickpea, lentil, black eye bean, millet, sorghum, oat, buckwheat, quinoa, rye, wheat, sweet potato slices and other various crops and grains.

It can be also used in cutting and rubbing maize straw, hay, potatoes seedling and weed. It is the ideal and professional grinding mill for the self-employed, farmers, livestock staff and animal feed factory.

Features:

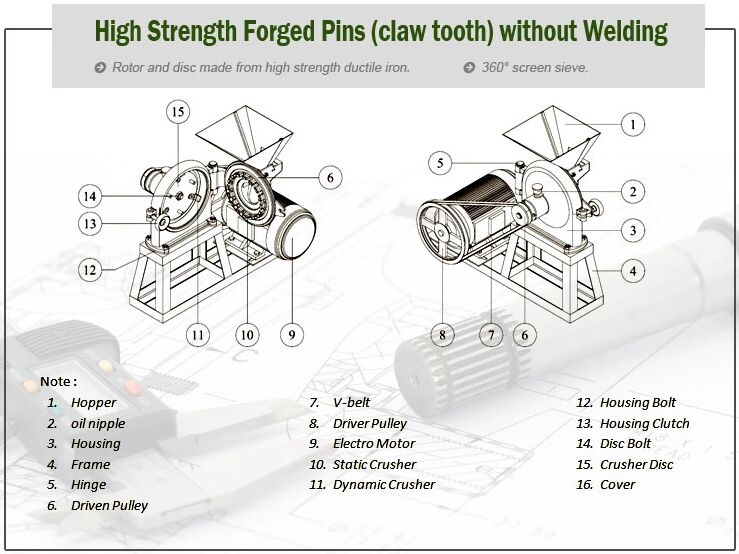

This Bambara Nut Flour Grinding Machine has reasonable structure, beautiful appearance, practicality, easy maintenance and operation method, safe and stable function, low engery consumption, convenient asseambling and disassembling, etc.

If installed with self-suction device, fan and discharger, then it will become more labour-saving and engery-saving.

Installation and Usage:

1. When we start to grind bambara nut, maize, beans and other grains, first lift up the flashboard of the feeding hopper, then the grains will flow into the crushing chamber automatically.

2. Discharging: for different grains processing, users can make a discharging cloth bag with two open ends. The cloth bag diameter: about 0.4m, length: about 4-6m. During working process, fasten the bag’s one end to the discharging outlet. If you want to change grains, no need of machine halting. Just keep the machine working. If you crush feed, then no need of using a discharging bag, but just a pit or other methods.

3. This machine has different meshes (or screen hole numbers) of sieves. Please tell us your requirement about the powder meshes. We can choose the suitable one for you. (As we know that posho meal is 40 meshes, which is popular in many African countries)

4. When we put the sieve into the machine, we should make the sieve’s inner lap keep along with the rotor’s rotation direction.

5. When grinding bean cake or bean chunk, sweet potato and other big raw material, we can crush the bean chunk into 20-40mm pieces, and sweet potato into 20-100mm length of pieces, and the sweet potato need slicing first and mixing with enough moisture.

Operation Instruction and Safety Precautions:

1. Please read this instruction first before operation.

2. The operator should wear mask and work hat. During the machine’s working process, the operator should not leave the duty post.

3. Don’t allocate high speed or low speed electric motor. The machine’s motor should have ground connection device. The working place should be ventilated and pay attention to the fire.

4. Clean the grain first before processing, such as stone, metal, etc.

5. Before working, check each connection part of the machine whether tight. Don’t open the machine door during working. If there has abnormal voice, then halt the machine. When the machine stops running, then check it.

6. Before working, have the running test first of the machine for 1-2 minutes, then feed into grains. Before halting, make the machine idling for 1-2 minutes and make the material discharged completely.

7. Children under the age of 16 and the old over 60 should not operate the machine by himself.

Vulnerable Parts:

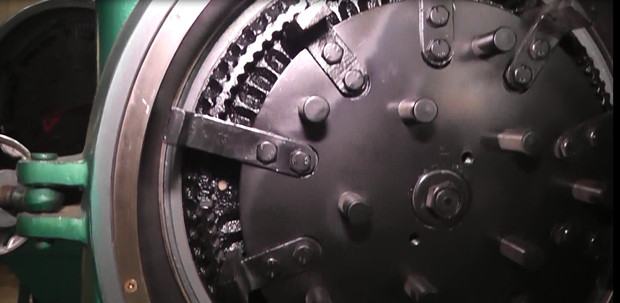

1.toothed disc 2.sieve 3.sieve circle 4.sieve nail 5.bearing 6.circular tooth 7.flat tooth 8.moving blade, stationary blade 9.hammer

VIDEO:

Technical Parameter:

|

Model |

Power |

Output (kg/h) |

Weight (kg) |

Number of 20 Feet Container |

|

|

Motor (kw) |

Diesel Engine (HP) |

||||

|

UGM-1 |

2.2-3kw /220v,50hz |

6 |

Maize: 240(powder:1.2mm) … |

48-68 |

180 sets |

|

UGM-3 |

7.5-11 kw/380v,50hz |

15 |

Wheat: 900(powder:1.5mm) Maize: 800(powder:1.2mm) Soybean: 260(powder:0.6mm) Sorghum: 350(powder:0.6mm) … |

138 |

42 sets |

|

UGM-4 |

11 kw/380v,50hz |

15 |

Wheat: 1100(powder:1.5mm) Maize: 950(powder:1.2mm) Soybean: 320(powder:0.6mm) Sorghum: 480(powder:0.6mm) … |

168 |

24 sets |

|

UGM-5 |

22kw /380V,50hz |

30 |

Wheat: 2500(powder:1.5mm) Maize: 1800(powder:1.2mm) Sorghum: 1500(powder:0.6mm) … |

460 |

6 sets |

|

UGM-6 |

30kw /380v,50hz |

|

Wheat: 3500(powder:1.5mm) Maize: 2500(powder:1.2mm) Sorghum: 2000(powder:0.6mm) … |

520 |

6 sets |

|

UGM-7 |

55kw /380v,50hz |

|

Wheat: 8000(powder:1.5mm) Maize: 5600(powder:1.2mm) Soybean: 3800(powder:0.6mm) Sorghum: 4800(powder:0.6mm) … |

980 |

5 sets |

This Bambara Nut Flour Grinding Machine has reasonable structure, beautiful appearance, practicality, easy maintenance and operation method, safe and stable function, low engery consumption, convenient asseambling and disassembling, etc.

If installed with self-suction device, fan and discharger, then it will become more labour-saving and engery-saving.

Technical Parameter:

|

Model |

Power |

Output (kg/h) |

Weight (kg) |

Number of 20 Feet Container |

|

|

Motor (kw) |

Diesel Engine (HP) |

||||

|

UGM-1 |

2.2-3kw /220v,50hz |

6 |

Wheat: 600(powder:1.5mm) |

48-68 |

180 sets |

|

UGM-3 |

7.5-11 kw/380v,50hz |

15 |

Wheat: 900(powder:1.5mm) Maize: 800(powder:1.2mm) Soybean: 260(powder:0.6mm) Sorghum: 350(powder:0.6mm) … |

138 |

42 sets |

|

UGM-4 |

11 kw/380v,50hz |

15 |

Wheat: 1100(powder:1.5mm) Maize: 950(powder:1.2mm) Soybean: 320(powder:0.6mm) Sorghum: 480(powder:0.6mm) … |

168 |

24 sets |

|

UGM-5 |

22kw /380V,50hz |

30 |

Wheat: 2500(powder:1.5mm) Maize: 1800(powder:1.2mm) Sorghum: 1500(powder:0.6mm) … |

460 |

6 sets |

|

UGM-6 |

30kw /380v,50hz |

|

Wheat: 3500(powder:1.5mm) Maize: 2500(powder:1.2mm) Sorghum: 2000(powder:0.6mm) … |

520 |

6 sets |

|

UGM-7 |

55kw /380v,50hz |

|

Wheat: 8000(powder:1.5mm) Maize: 5600(powder:1.2mm) Soybean: 3800(powder:0.6mm) Sorghum: 4800(powder:0.6mm) … |

980 |

5 sets |

Any change of technical parameters, there is no further notice.

Copyright: Zhengzhou UGOOD Machinery Equipment Co., Ltd. info@corn-thresher.com Tel: 0086-135-2306-3891 Address: No. 7 Gaocun Guanzhuang Industrial Park, Zhengzhou, Henan, China