Products List

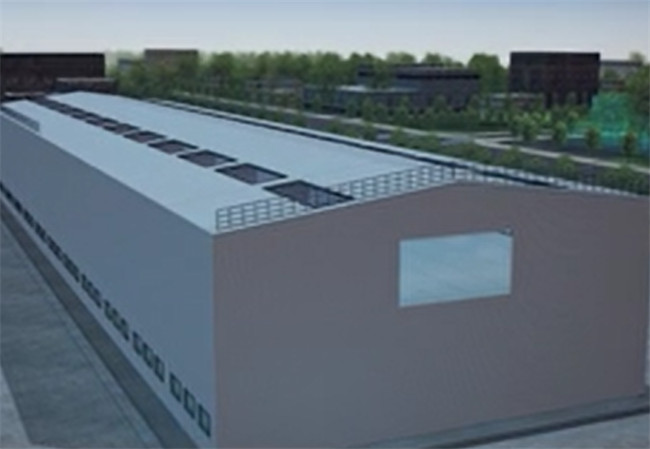

Corn Cobs Drying Line or Maize Ears Drying Plant: we can design the capacity 300T(3-5T/Hour) -1200T. This is the Steel Structure Construction Process Demonstration:

1. Foundation excavation;

2. Backfilling of sand and gravel materials;

3. Foundation construction;

4. Foundation backfilling and ground concrete pouring;

5. On-site splicing of wall steel frame;

6. Laying special sealant for steel structure to ensure the overall airtight effect of the drying warehouse;

7. Installation of interior wall panels;

8. Insulation cotton installation;

9. Installation of external wall panels;

10. Splicing of steel frame on roof of warehouse;

11. Installation of the inner panel of the warehouse roof;

12. Insulation cotton installation;

13. Installation of the outer panel on the roof of the warehouse;

14. Wall hoisting;

15. Bolt connection;

16. Hoisting on the top of the warehouse;

17. Railing and canopy installation;

18. Installation of edge banding board;

19. Installation of the support frame of the belt conveyor on the roof of the warehouse;

20. Installation of other equipment.

We design, manufacture and install the custom-built solutions for your corn ears drying, reasonable and scientific, highly advanced and automatic, and cost-efficient!

We can design the capacity 300T(3-5T/Hour) -1200T.

Any change of technical parameters, there is no further notice.

Copyright: Zhengzhou UGOOD Machinery Equipment Co., Ltd. info@corn-thresher.com Tel: 0086-135-2306-3891 Address: No. 7 Gaocun Guanzhuang Industrial Park, Zhengzhou, Henan, China